Blog

Breakthrough Research on Turnout Gear Protective Fabric Could Keep Firefighters Safer

The fabrics were immersed in water at temperatures ranging from 60 to 95 C for up to 1,200 hours. After exposure, some of them lost significant tensile strength — the stress a fabric can withstand without splitting or breaking — without showing any visible signs of degradation.

The cause was found to be the high sulphur content in some of the fibres, leading to an accelerated loss in fabric strength when exposed to moisture. That degradation weakens the safety of protective garments when exposed to sweat, water, rain, snow or laundering.

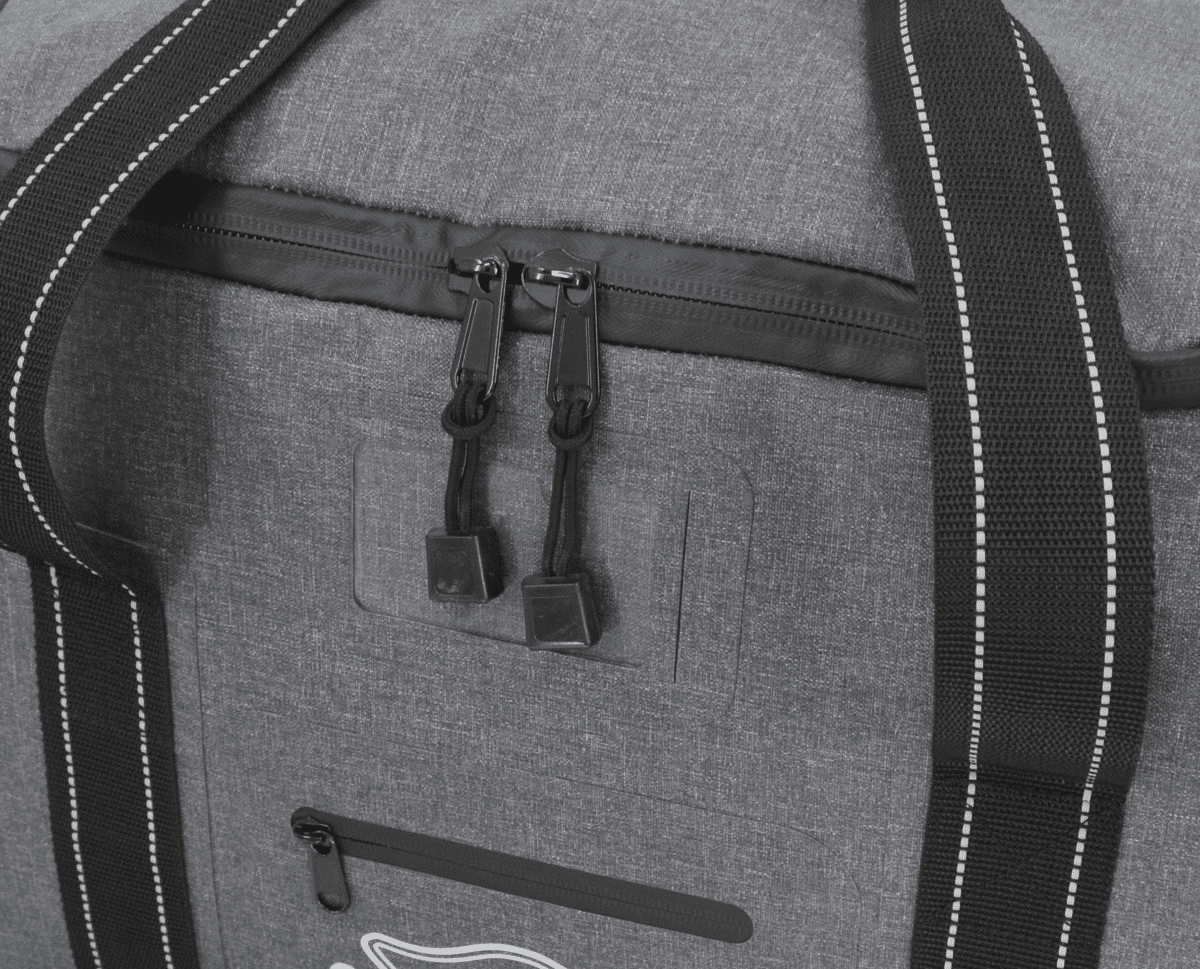

In 2019, Lightning X developed the LXFB99 – an air tight/water tight turnout gear bag designed to protect firefighters from prolonged exposure to carcinogens and off-gassing from contaminated turnout gear until the gear can be cleaned and sanitized at the station.

All seams on the main compartments of the bag are heat welded, so there are no stitches that penetrate the bag to allow air or particulates to escape (think: moisture barrier on turnout gear). Since the fabric is waterproof, the inside and outside can be cleaned and washed out with a hose to remove any remaining contaminants after the dirty turnout gear is removed and washed.

We’ve done a blog post in the past about the extreme damage that UV rays from the sun can cause to turnout gear fabrics. Now with moisture also becoming a huge issue, it’s more important than ever to not only keep your gear protected from the elements, but also keep firefighters protected from the carcinogens that are inherently found in turnout gear.

Clearance

Clearance

OSHA First Aid Kits

OSHA First Aid Kits Portable First Aid Kits

Portable First Aid Kits

New

New Supplies

Supplies